Services

ManufacturingDragon Engineering offers a variety of in-house additive and subtractive manufacturing capabilities. These services allow us to operate independently, yielding shorter lead times and more control over the finished product.

Our manufacturing services are well suited for rapid prototyping and small batch manufacturing.

Services

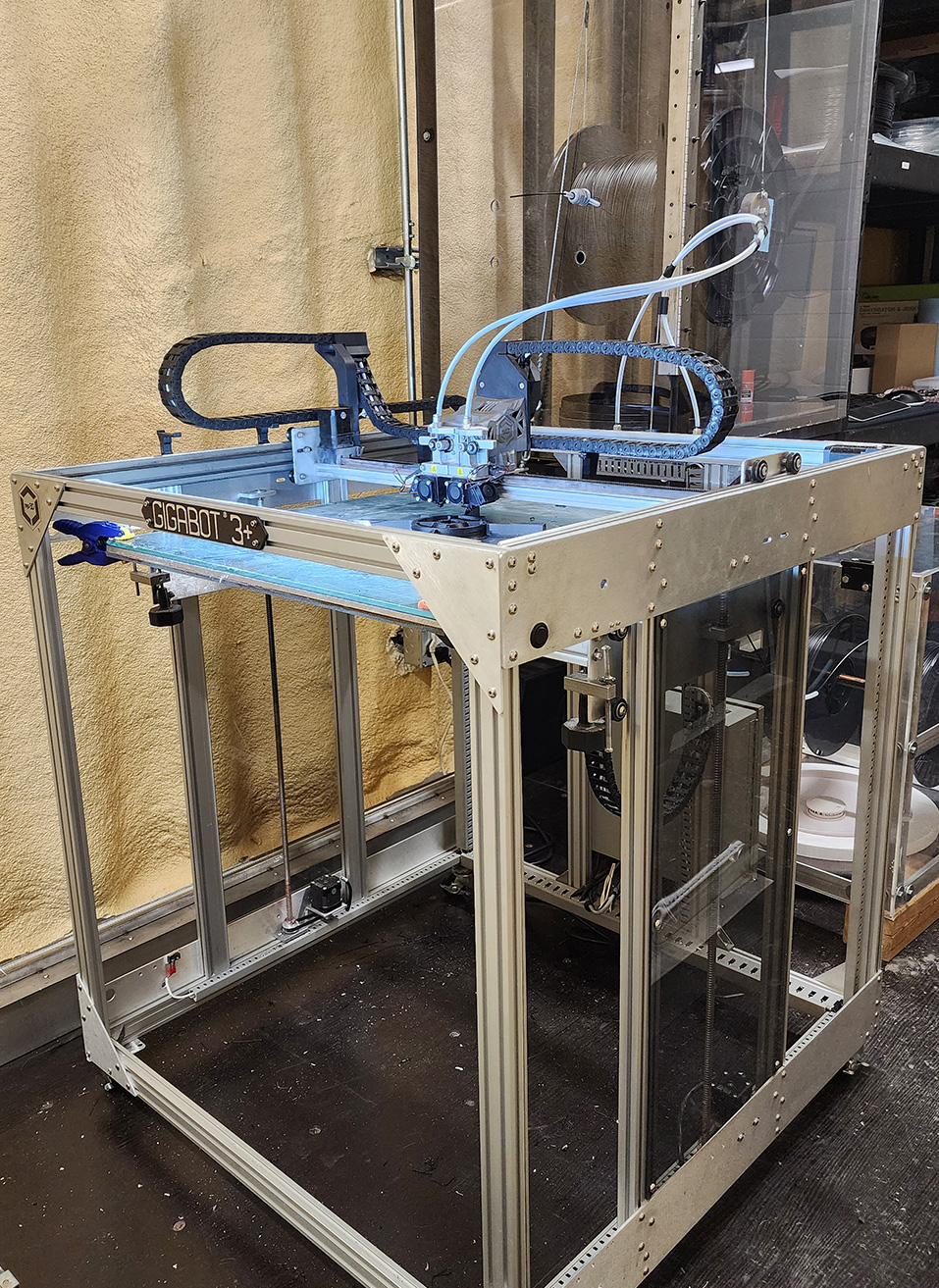

3D Printing

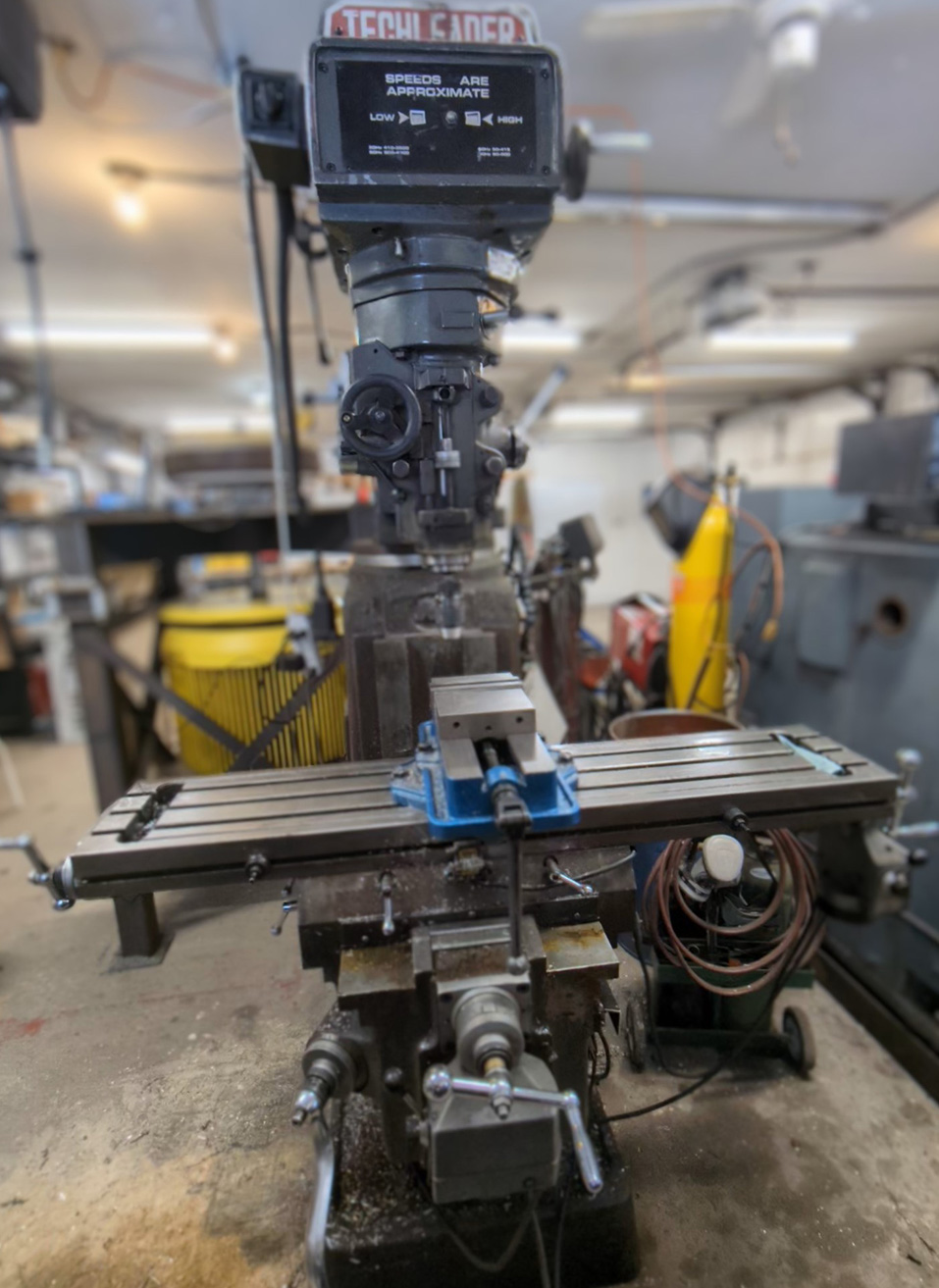

Machining

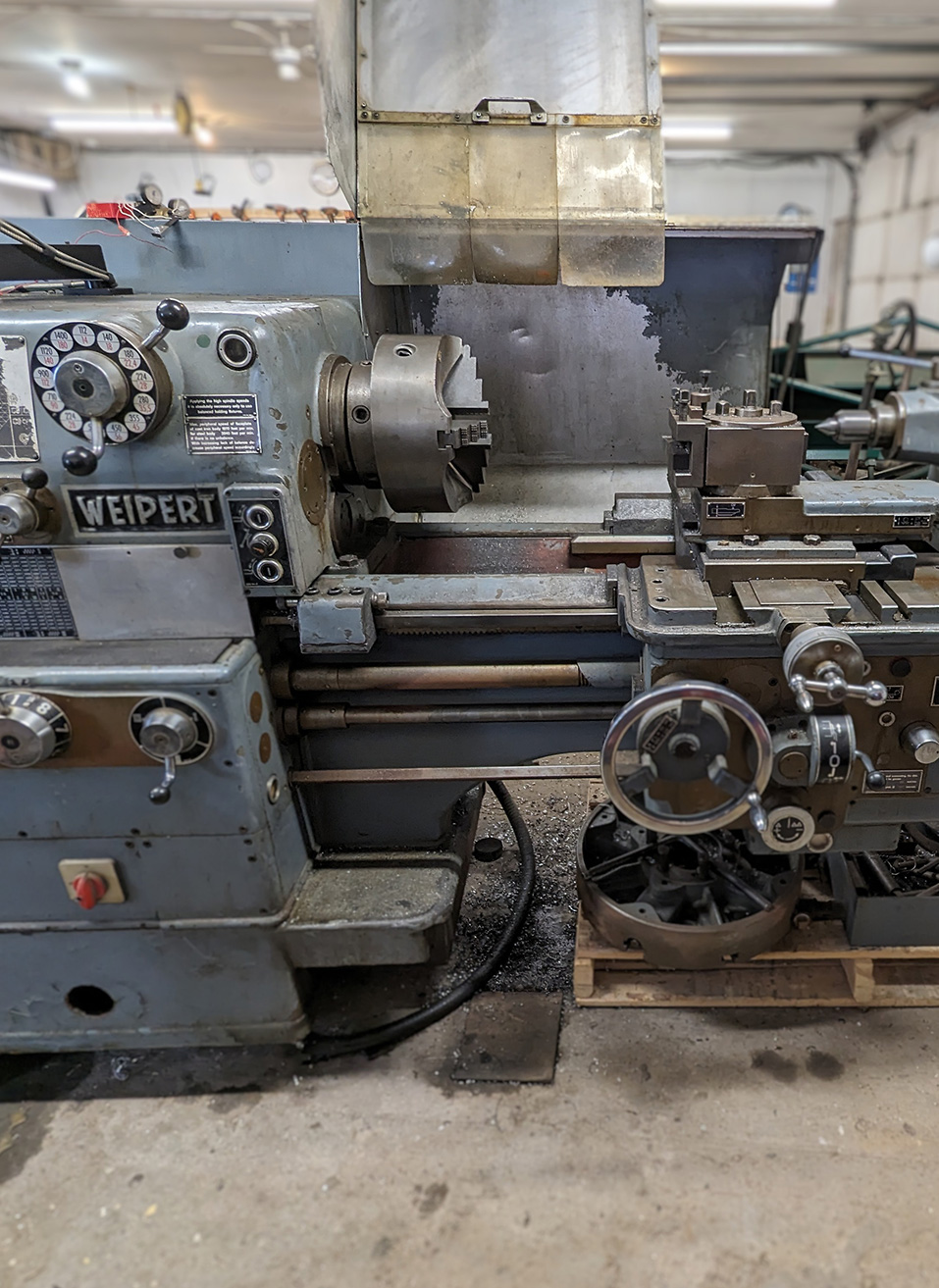

Turning

Bending

Welding

Capabilities

Manufacturing

| Model | Specs | |

| 3D Printing | RE:3D - Gigabot 3.0+ | Build Size: X 23.2", Y 23.6", Z 23.6" |

| Nozzle size: up to 0.8mm | ||

| Max Nozzle Temp: 320 °C | ||

| Typical Materials: PLA, PETG, PETG-CF, PA, PA-CF, ABS, ASA | ||

| Erectorbot - EB844HD | Build Size: X 48", Y 96", Z 48" | |

| Nozzle size: up to 1.2mm | ||

| Max Nozzle Temp: 280 °C | ||

| Typical Materials: PLA | ||

| Welding | Lincoln - Tig 200 Square Wave | Aluminum, Steel, Stainless |

| L-Tec - Migmaster 250 | ||

| Lincoln - Migpak 3200 HD | ||

| Bending | Tennsmith - HBU48-16 | Bending length: 48" |

| Bending thickness: 16 Gauge | ||

| Machining | Bridgeport Series II | Table Size: 10" x 54" |

| Travel: X 40", Y 17.5", Z 17.5", Quill 5" | ||

| Power: 5 HP | ||

| Weipert - W500 | Turning Length: 63" | |

| Turning Diameter over bed: 26-3/4" | ||

| Turning Diameter over tool: 14" | ||

| Hole through spindle: 2-1/2" | ||

| Power: 15 HP | ||

| Other Capabilities | 50 ton press | Bed Width: 31-1/2" |

| Max Height: 34" | ||

| Stroke: 7" | ||

| Magnetic drill press | Max cutter diameter: 1-5/8" | |

| Power source: 120V, 15A | ||

| SDS-MAX hammer drill | Max drill diameter: 1-3/4" | |

| Power source: Battery | ||

| 3/4" Drill | Speed: 350 RPM (not adjustable) | |

| Power source: 120V, 20A |